Business Management

Signs You Need to Replace Temporary Power Equipment

If you work in close proximities with temporary power equipment, it’s crucial to be aware of signs that indicate the equipment will soon need repairs or maintenance. If these signs are left untreated, the emergency or temporary power equipment could be damaged or broken and lead to dire complications. When noticing equipment is starting to show signs of wear or damage, it might be time for a replacement. In this blog article, our temporary power experts will explain some of the most noticeable signs that will help you come to the realization that it’s time for an upgrade or repair.

When To Replace A Generator

Generators are a great investment for any homeowner or business owner and are lifesavers when power outages occur. Amid a natural disaster, a generator will ensure that the electrical system doesn’t lose power. However, as with any piece of electrical equipment, generators are subject to wear and tear. Here are 8 signs that indicate that it’s time for a generator upgrade.

- Visible signs of damage – Visible signs of wear and tear can include dust, debris, or excessive corrosion from exposure to extreme weather conditions. If there is visible see rust on the outside, the engine inside might have rust as well and a maintenance test may need to be scheduled.

- Fuel problems – If fuel lines are damaged, the generator could be starved for fuel and could stall or be unable to start. Old, corroded fuel lines could mean fuel is leaking or connections may be loose. Diesel generators can develop sludge and clog the fuel lines. As the generator begins to wear down it will not as efficient anymore and could require more fuel to operate. If a generator is constantly burning through fuel, it may be time to consider a replacement.

- Unusual smells and noises – Strange smells coming from a generator could indicate electrical components are burning, an exhaust leak, or gas leak. If there are any unfamiliar noises, it could be mechanical components not working properly. If left alone, these issues can cause more damage so don’t ignore any unusual noises or smells from the generator.

- Start-up issues – New Standby Generators are designed to turn on automatically with the support of an automatic transfer switch when power is lost, so if it’s not the transfer switch causing problems, the generator is likely in need of maintenance.

- Inconsistent performance – A drop in performance isn’t detrimental but during an outage, backup power needs to be reliable. There should be a constant supply of steady power. If appliances can’t run off the generator or lights are flickering, it’s a clear sign to check on the generator.

- Repairs becoming expensive and more frequent – As backup generators age, the repairs can become more frequent. Regular maintenance is necessary, but if several components need to be fixed more than once or twice a year, it’s probably time to invest in a new generator. Repairs can become more complicated and more expensive if they need parts that are older and difficult to find.

- Power needs exceed its output – The generator may have initially suited the power requirements, but now there may be a larger load, and the generator can no longer supply enough power to support it. If a generator is too small to power the specific load, appliances are more likely to fail, the generator may cut out, or even overheat.

- Reaching the end of its lifespan – Generators are designed to last long, but its age is truly dependent on how often it gets used. Frequent use means it needs a replacement sooner than light use (once or twice a year). As it nears the end of its service lifespan, you’ll probably notice some other signs mentioned above as indicators of this. The generator may contain older technology that the manufacturer no longer supports and can makes repairs tedious. Newer generators will include features that will simply the operation. (i.e., phone applications to monitor the status of your generator from anywhere).

The backup source of power to a home or business needs to be reliable 24/7. Catch these signs early before the lights go out and don’t fall behind on scheduled maintenance for your generator. Having a reliable generator will ensure that you will have power when you need it. For more information on generators, read our previous blogs written by our experts here at Power Assemblies.

Industries That Require Backup Generators

Connecting Your Home to A Generator Via Transfer

When To Replace Electrical Cables

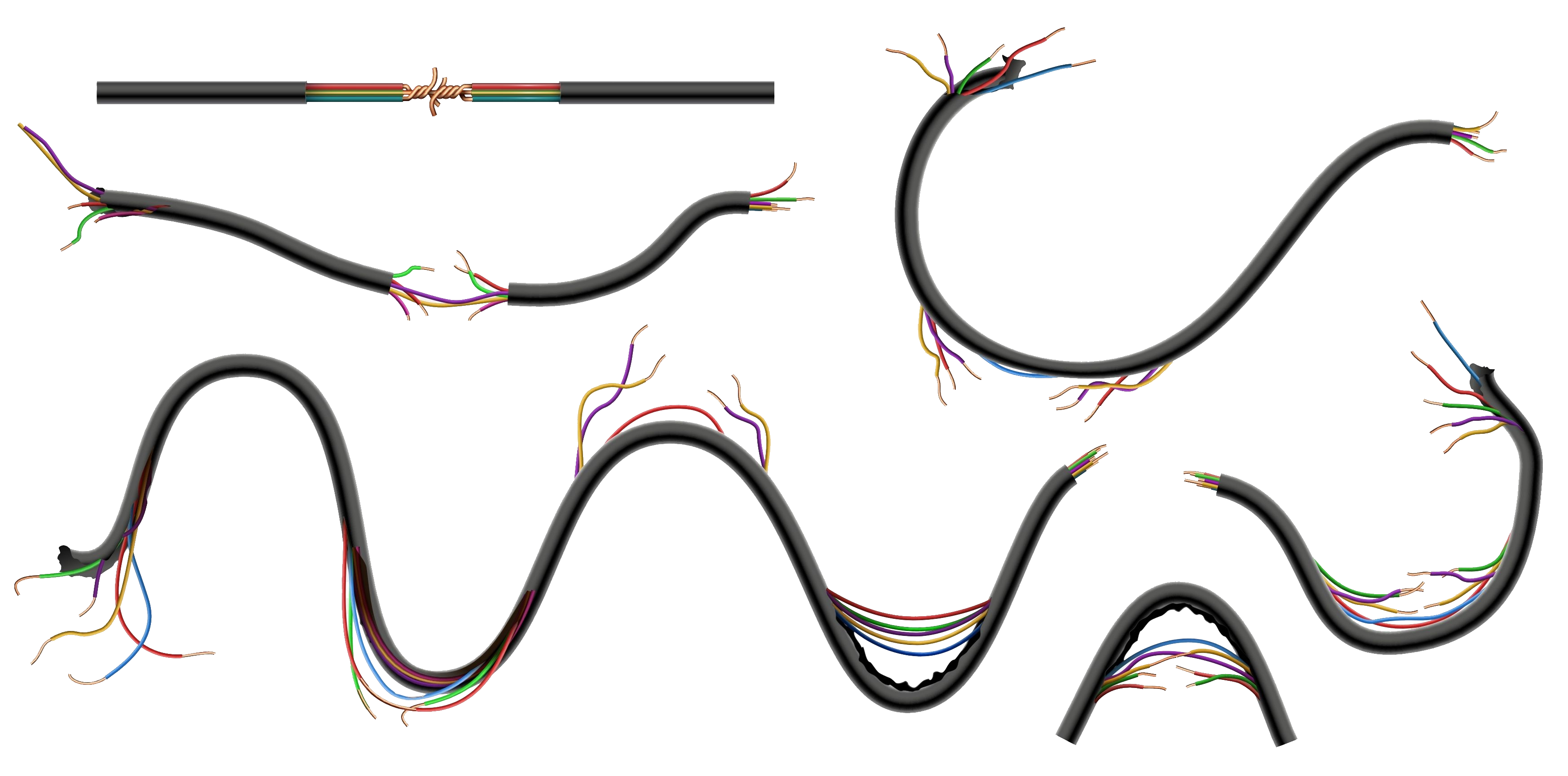

Cable assemblies have a long service lifetime if they are properly used but there are several factors that could lead to the failure of a cable system and cause the deterioration or failure of electrical equipment. These failures can be disruptive, expensive, and hazardous. What are the signs that you might need to repair or replace your cables?

- Ageing – Over time cables will show signs of ageing such as embrittlement, cracking, and withering. If the insulating and sheathing materials break down, it exposes the conductor and risks a potential short circuit which could cause an electrical fire.

- Misuse – Electrical cables are made of materials designed to perform in optimal conditions. Using a cable that is not appropriate for the application (i.e not resistant enough to harsh outdoor environments or tough enough against exposure to chemicals) makes it more likely to fail. Cables can be run over or snagged on at job sites causing stress to the wires inside. Constant bending and twisting while in use can lead to irreversible straining of the conductor wires where they can begin to break or sever and pierce the insulation wall.

- Moisture – Constant exposure to moisture will deteriorate the insulation material or jacket and could cause short circuits and corrosion to the copper or aluminum components inside the cable. Cables exposed to water while energized can propose a sever electrical hazard to those in close proximities with the live circuit. These cables would also be more susceptible to water treeing, which can create electrical stress and causes the insulating jacket to crack.

- Overheating – Excessive heating of the cable will cause degradation of the insulation and sheathing material. This can be a result of sun exposure, proximity to high temperature sources, insufficient ventilation, or overloading. If the cable is underrated for the application, it will overheat. So be sure to always use cables rated for the intended usage.

- Pests – Rodents can chew the outer layer of cables and it could affect the cable’s ability to properly conduct electricity.

- UV exposure – Too much UV exposure can cause fading and cracking of the insulation.

- Nicks and cuts – If a cable contains have nicks and cuts, they are no longer capable of carrying the rated amount of current through the damaged portion and should be put aside immediately. If the nick is deep enough, the wire will overheat and result in an electrical fire. Impact or contact with sharp objects can lead to cuts in the jacket. If this is the case, it is certainly time for a replacement or repair.

- Exposed wire – Unprotected wires increases the possibility of electrical fires and electrical shock tremendously. If an exposed wire is present, it should de-energized and repaired immediately.

It’s important to catch these signs early before they become major issues. We understand that cable assemblies are expensive and that’s why we offer our Cable Repair Program here at Power Assemblies! We can restore damaged cables to like new conditions to extend their life and maximize your return on investment. While some damages can render cables no longer useful, it doesn’t mean every sign of impairment should have you buying new cables. Sign up for our repair program today by filling out the form here, or you can call us at (866)-825-8525 or email us at [email protected].

Alternative To Metal Spider Boxes

Spider Boxes are vital for portable power in disaster relief situations, events and entertainment venues, construction sites, and more. They are a safe, convenient, and economical way to provide power to tools and temporary lighting systems. Used in a wide range of applications, Spider Boxes are durable and dependable but many of metallic boxes are purchased for one job and are often discarded after the job is complete.

Metallic Spider Boxes don’t last very long because they are so easily damaged on job sites. If not careful, construction equipment such as backhoes or forklifts can run them over. Metal Spider Boxes can get battered by rocks and dirt leaving dents and scratches. Their life cycle typically only lasts for one season and its redundant to replace them so often.

The Power Assemblies “Beetle Box” Spider Boxes are made from rugged nonmetallic rubber that helps with insulation and safeguards them from rust. Rubber enclosures are more durable and safer than metal because they can take more of a beating! Consider offering our unique Beetle Boxes to your customers for their various uses and see how they are small but mighty.

To learn more about Power Assemblies Spider Boxes, visit out our previous blogs below.

Introducing the NEW Marine Beetle Box (Spider Box)

Beetle Box: Purpose and Benefits

Temporary Power Equipment Safety

Electrical safety is to be taken very seriously. If the electrical equipment is still working with clear and evident damages, it is not safe! There are plenty of benefits to upgrading your temporary power equipment: increased safety, reliability, energy efficiency, and peace of mind that the equipment is working as it should and is not a liability. It’s crucial to take the time to look for the signs that indicate it’s time to replace or repair emergency power equipment because negligence can cause injury and damage to others. If you have any questions after reading this blog, please contact our team by emailing us directly at [email protected] or call us today at (866)-825-8525.