News

Generator Docking Station Vs. Load Bank Station

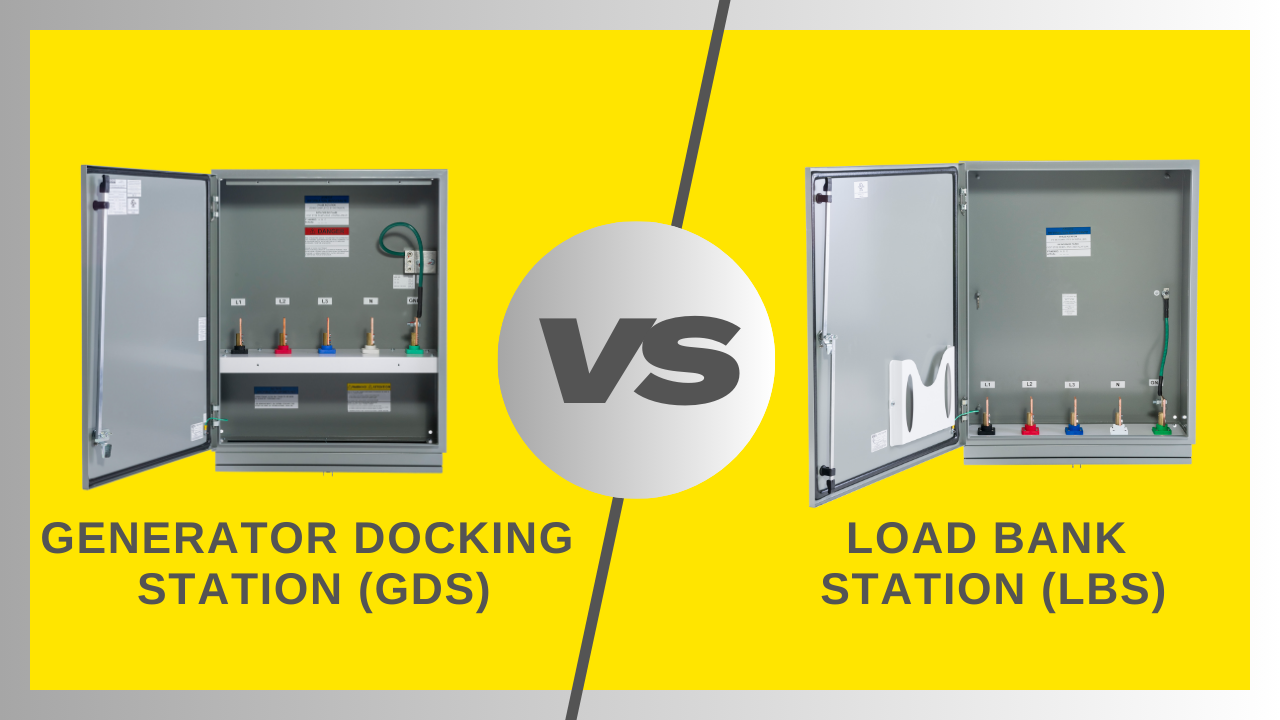

A Generator Docking Station and Load Bank Station are fundamental for any business that wishes to succeed when faced with a power outage. Imagine being in the midst of a busy workday when an unexpected blackout strikes. If you have the right equipment in your backup power system, there is nothing to worry about! That is, while generators play a central role in providing backup power, they rely on other pieces of equipment to distribute the electricity that it generates to downstream machinery. For this purpose, a Transfer Switch and a Generator Docking Station (GDS) are responsible for making sure that your generator is properly connected and ready to act in the event of a power outage.

At first glance, Load Bank Stations (LBS) appear almost identical to a GDS. However, they are designed to support your generator in contrasting ways. Rather than assisting your generator as it powers a home or business, a LBS provides a means of testing your generator to guarantee that it will be able to generate and deliver its rated electrical capacity.

So, in what other ways are a GDS and LBS similar, yet different? To best answer your question, our electrical experts will spend this article comparing each of these power distribution units and explore their unique roles in a portable power system. This way, you can better understand both of these power products and pair your customers with the right solution for their needs.

What Makes a Generator Docking Station and a Load Bank Station Alike?

As top-notch power solutions that are designed to keep operations running smoothly during a power outage or electrical testing, the LBS and GDS share some common ground. To start, both power distribution units are crafted with grade-A materials. Standard models include a NEMA 12/4 rated weather-proof enclosure, cULus-listed components, and industry-standard Series 16 Camlocks. We choose to include only premium materials in our equipment so that we can provide reliable performance and peace of mind, especially in emergency situations.

Our quick-connect camlock system is another feature that the LBS and GDS have in common. This ergonomic feature uses Series 16 Camlocks to help simplify your installation process, saving you time and labor costs. Whether your customers are facing a time-sensitive power emergency or are performing routine maintenance, this feature proves itself invaluable. Plus, each of these power distribution units are available with an affordable price tag to easily work into your budget.

We offer our LBS and GDS in a wide range of standard configurations to cater to your customer’s unique power distribution needs. While using the product configurator located on our website, you can easily mix and match dozens of specifications to create the perfect configuration for your customer’s project. Our standard configuration Load Bank Station and Generator Docking Station are available with an incredibly fast 0-4 week lead time to promptly provide your customers with the equipment they need to get the job done.

However, if you ever require equipment outside of our standard models, we offer tailor-made equipment at your request. You can contact us by emailing [email protected] to submit your inquiry for a customized LBS or GDS.

Standard 400A, 120/208V Generator Docking Station

What Are The Differences Between a Generator Docking Station and Load Bank Station?

As we briefly mentioned, a GDS and a LBS serve different purposes in your customer’s power system. Because of this, they have different styles of inputs and outputs that are specifically designed for their distinct function. Generator Docking Stations use Male Series 16 Camlocks to connect with a generator and carry electricity into a backup power system. After electricity has entered and circulated throughout the GDS, it uses bus bars to carry electricity out of its enclosure to power downstream equipment.

If a generator fails to provide your backup power system with the correct amount of power, it can lead to devastating consequences. This is why our LBS is engineered to work in tandem with other load bank testing equipment to ensure that your generator is prepared to perform in case of an emergency. Load Bank Stations are specially designed to carry electricity away from its enclosure to assist in testing the load capacity of a power system. They use Female (hot) Series 16 Camlocks to quickly install for testing and include a silver-plated copper busbar output to effectively transport electricity.

The Load Bank Station is available with a NEMA 4/12 carbon steel, standard and large-sized enclosure to accommodate various load testing applications and keep your backup power system running at peak efficiency. Our GDS, on the other hand, is available with a miniature, standard, or large-sized enclosure with options for NEMA 4/12 carbon steel or NEMA 4X SS stainless steel to suit your customer’s needs and preferences.

Our LBS and GDS are offered in single-phase or three-phase configurations depending on the need of the project. The load bank station is available in (3) standard variations including 400A, 800A, or 1200A, but we can build you a custom LBS up to 5000A if needed. The GDS is offered in a slightly wider variety of standard amperage configurations including 400A, 800A, 1200A, 1600A, and 2000A. However, if you need a larger unit we are happy to accommodate you with a custom box. Simply contact us at [email protected] and one of our sales engineers will be happy to accommodate you.

Standard-Sized 800A, 208V Load Bank Station

If you have any questions or would like to learn more about our selection of Generator Docking Stations and Load Bank Stations, please contact us at (866)-825-8525 or send us an email at [email protected].